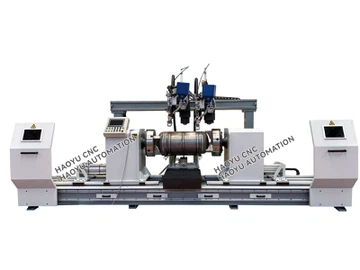

Automatic Circumferential And Straight Seam Integrated Welding Machine

I.Main features

- Multi-functional and highly versatile: This is its biggest advantage. One machine meets the needs of two main weld types, saving on equipment procurement costs and factory space.

- High automation and high efficiency: The fully automated process reduces reliance on manual welding skills, ensuring stable welding speed and high production efficiency, making it particularly suitable for mass production.

- Stable and reliable welding quality: The automated process eliminates human error, resulting in aesthetically pleasing, consistent weld formations with a low defect rate.

- Easy operation and programming: The modern control system has a user-friendly interface, simple parameter settings, and can store multiple welding programs for easy recall.

- High flexibility: By adjusting the fixtures and programs, it can adapt to workpieces of different diameters, lengths, and thicknesses, offering a wide range of applications.

II.Main components

1.Main Machine Body and Bed: A robust mechanical structure providing a stable foundation for the entire system.

2.Welding Power Source: Provides the energy required for welding, such as TIG welding, MIG/MAG welding, plasma welding, or laser welding, selected according to the process.

3.Circumferential Seam Welding Station:

- The chuck is typically mounted on one end of the spindle, and a servo motor is installed in the spindle box. Its core function is to drive the chuck to precisely clamp and rotate the workpiece. On the other side, a cylinder holds the workpiece in place to ensure the welding position is horizontal and to guarantee perfect welding quality.

- The left-right swinging mechanism of the welding torch can significantly widen the weld seam, making the heat distribution more uniform and effectively avoiding welding defects such as undercut and lack of fusion.

4.Straight Seam Welding Station:

The worktable of the straight seam welding machine is fixed, while the welding torch can move on the guide rail to perform welding of circumferential and straight seams.

5.The core control system of this integrated circumferential and straight seam welding machine consists of a programmable logic controller (PLC) and its expansion modules. The PLC acts as the brain of the entire welding process, responsible for precisely coordinating the rotation of the welding torch, the movement of the workpiece, and the execution of welding parameters. To meet the complex requirements of both circumferential and straight seam welding processes, the system adds extra input/output points and specific function interfaces through expansion modules, enabling the connection and control of more sensors, actuators, and peripheral devices.

III.Working principle

- Mode 1: Circumferential Seam Welding Mode

Clamping: Clamp the cylindrical workpiece between the headstock and tailstock.

Torch Alignment: Adjust the welding torch position to align with the weld start point.

Welding: Start the program; the headstock rotates the workpiece at a constant speed, while the welding torch starts and makes small oscillations. The entire circumferential seam is welded after one complete rotation of the workpiece.

- Mode 2: Straight Seam Welding Mode

Clamping: Place the workpiece to be welded (flat plate or split-slit cylinder) into the straight seam fixture, and use keys or pressure plates to firmly hold both sides of the weld.

Torch Alignment: Adjust the welding torch to the starting end of the straight seam.

IV.Other products for your reference

Other products for your reference

Fuel tank straight seam welding machine

Laser longitudinal seam welding machine

Automatic butt linear seam welding machine

Air compressor circular seam welding machine

Air tank round seam welding machine

SAW double circular seanm welding machine

Hot Tags: automatic circumferential and straight seam integrated welding machine, China, manufacturers, suppliers, factory